YB∕T 5292-2017 高炉炭块氧化性试验方法/Test method for the oxidation-resistance of carbon blocks for blast furnaces

高炉炭块氧化性试验方法

1 范围

本标准规定了高炉炭块氧化性试验的方法原理、仪器设备、试样制备、试验步骤、结果计算及试验报告。

本标准适用于高炉炭块氧化性的测定,矿热炉用炭块也可参照使用。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 1427 炭素材料取样方法

GB/T 8170 数值修约规则与极限数值的表示和判定

3方法原理

高炉炭块的氧化性是指一定形状的炭块试样在 1100℃温度下,以二氧化碳为氧化剂,在 1h 内试样氧化失重的百分数。

4 仪器、设备和材料

4.1 电子天平:最大称量范围 220g,感量 0.01g。

4 2竖式电炉:最高温度可达 1200℃以上,内置 φ60mmx900mm 或 φ100mmx600mm 刚玉管。

4.3自动控温仪:控温范围 0~1600℃,精度±1℃。

4 4干燥箱:室温~300℃,控温精度±5℃。

4.5铂丝:p0.3mm。

4.6气体流量计:0~10L/min,精度±0.5L/min。

4.7 二氧化碳气体:纯度不小于 99%。

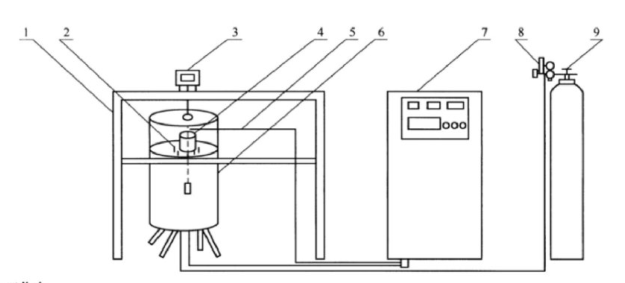

4.8 氧化性试验装置如图1所示,

5 试样制备

5.1 试样的采取按 GB/T 1427 规定进行。

5.2 将取得的试样去掉疏松、粗糙的表层,然后加工成 φ30mmx60mm 的圆柱体试样,加工精度为±0.5mm,两端面保持平行并垂直于轴线,表面无大于 2mm 的凹缺陷。

5.3 在距离试样一端 8mm 处,沿垂直轴线方向钻一直径为 3mm 的孔作为吊试样用。

5.4 加工好的试样需在 120℃~130℃的干燥箱中经 2h 烘干备用。

5.5 每个试块取 2个试样。

6 试验步骤

6.1 用 φ0. 3mm 的铂丝将烘干后的试样悬吊在刚玉管的恒温区中,上端悬吊在天平下端的挂钩上,并确保试样不得与刚玉管壁接触,以免影响称景。

6.2 送电升温前,调好天平的零点,记下试样和铂丝总质量。

1-工作台;

2-发热元件;

3-电子天平;

4-刚玉管;

5-补偿导线;

6-高温炉;

7-控温器;

8-流量计;

9-气源。

图1 氧化性试验装置图

6.3 送电升温,升温速率不大于 10℃/min。6.4 炉温升至 500℃时开始通二氧化碳气体,流量为 5L/min,温度达到 1100℃后开始恒温,控制在1100℃±5℃,保持 3min~5min 使温度恒定后记录试样与铂丝总质量,并开始计时。6.5 由于氧化,试样将减量,每隔 10min 记录一次质量并检査炉温和二氧化碳气体流量是否正常,待试样恒温氧化 1h 后结束试验。

7 结果计算

7.1 试样氧化失重率 K(%)按式(1)计算:

式中:

K-试样氧化失重率,单位为质量百分数(%);

m1–1100℃±2℃试验开始时试样质量与铂丝质量之和,单位为克(g);

m2:–1100℃±2℃试验结束时试样质量与铂丝质量之和,单位为克(g);

m3:–铂丝的质量,单位为克(g)。

7.2 试验误差不得超过 0.5%,试验结果取两次试验的平均值,结果保留小数点后两位,数值修约按GB/T 8170 规定进行。

8试验报告

试验报告应包括下列内容:

a)委托单位;

b) 试样名称;

c)试样编号;

d)试验条件;

e)试验结果;

f)试验单位;

g)试验人员;

h)试验日期,

Test method for the oxidation-resistance of carbon blocks for blast furnaces

1 Range

This standard specifies the method, principle, equipment, sample preparation, test procedure, result calculation and test report of oxidizing test of carbon block in blast furnace.

This standard is applicable to the determination of oxidizing property of carbon block in blast furnace.

2 Normative reference documents

The following documents are essential for the application of this document. For dated references, the date-only version applies to this document. For undated references, the latest version (including all amendment orders) applies to this document.

GB/T 1427 Method for sampling carbon materials

GB/T 8170 numerical revision rules and limit value representation and judgment

3 Method Principles

The oxidizability of carbon block in blast furnace refers to the percentage of oxidized weight loss of a sample of carbon block with a certain shape within 1h at 1100℃ with carbon dioxide as oxidant.

4 Instruments, equipment and materials

4.1 Electronic balance: maximum weighing range 220g, sensitivity 0.01g.

4.2 Vertical electric furnace: the maximum temperature can reach 1200℃ or above, built-in φ60mmx900mm or φ100mmx600mm corundum tube.

4.3 Automatic temperature control instrument: temperature control range 0~1600℃, accuracy ±1℃.

4 4 Drying box: room temperature ~300℃, temperature control accuracy ±5℃.

4.5 Platinum wire :p0.3mm.

4.6 Gas flow meter :0~10L/min, accuracy ±0.5L/min.

4.7 Carbon dioxide gas: purity is not less than 99%.

4.8 Oxidation test device is shown in Figure 1.

5 Sample preparation

5.1 Samples shall be taken in accordance with GB/T 1427.

5.2 Remove the loose and rough surface layer of the obtained sample, and then process it into a cylindrical sample of φ30mmx60mm with a processing accuracy of ±0.5mm. The two ends shall be kept parallel and perpendicular to the axis, and no concave defect larger than 2mm shall be found on the surface.

5.3 Drill a hole with a diameter of 3mm along the vertical axis at a distance of 8mm from one end of the sample for lifting the sample.

5.4 The processed sample shall be dried in a drying oven at 120 ° C ~130 ° C for 2h for use.

5.5 2 samples are taken for each test block.

6 Test Procedure

6.1 Use φ0.3mm platinum wire to suspend the dried sample in the constant temperature zone of the corundum tube, with the upper end suspended on the hook at the lower end of the balance, and ensure that the sample is not in contact with the corundum tube wall, so as not to affect the weighing view.

6.2 Before heating up, adjust the zero point of the balance and record the total mass of the sample and platinum wire.

1– Work table;

2- heating element;

3- Electronic balance;

4- Corundum tube;

5- Compensation wire;

6- high temperature furnace;

7- Temperature controller;

8- Flowmeter;

9- Air source.

FIG. 1 Oxidation test device diagram

6.3 Heating up with power supply, the heating rate is not more than 10℃/min. 6.4 When the furnace temperature rises to 500℃, carbon dioxide gas starts to be discharged, the flow rate is 5L/min, the temperature starts to be constant when the temperature reaches 1100℃, and the temperature is controlled at 1100℃±5℃. After keeping the temperature constant for 3min~5min, the total mass of the sample and platinum wire is recorded, and the timing starts. 6.5 The sample will be reduced due to oxidation. Record the mass every 10min and check whether the furnace temperature and carbon dioxide gas flow are normal. The test will be completed after the sample is oxidized at constant temperature for 1h.

7 Result Calculation

7.1 The sample oxidation weight loss K(%) is calculated according to formula (1) :

Formula:

K-sample oxidation weight loss, unit is percentage of mass (%);

m1–1100℃±2℃ Sum of sample mass and platinum wire mass at the beginning of the test, in grams (g);

m2:–1100℃±2℃ Sum of sample mass and platinum wire mass at the end of the test, in grams (g);

m3:– The mass of the platinum wire, expressed in grams (g).

7.2 The test error shall not exceed 0.5%, the test result shall be the average value of the two tests, the result shall be retained after two decimal places, and the numerical correction shall be carried out according to GB/T 8170.

8Test report

The test report shall include the following:

a) the entrusting unit;

b) sample name;

c) Sample number;

d) Test conditions;

e) Test results;

f) test unit;

g) Test personnel;

h) Test date,